Explore the captivating realm of metalworking, where old meets new. Discover the rich history behind metal fabrication. This craft has shaped human progress since ancient times.

Welding and metal machining offer more than just technical know-how. They link you to a legacy of skilled craftsmen. These artisans developed amazing techniques over centuries.

The Neolithic era saw the birth of metalworking. Cultures worldwide created innovative methods to shape metals. Ancient societies mastered practices that still inspire today’s artisans.

Andean civilizations showed exceptional metalworking skills. They created intricate artifacts with remarkable craftsmanship. Their techniques, from copper smelting to gold artistry, form the basis of modern metalworking education1.

Key Takeaways

- Metalworking has a rich history spanning thousands of years

- Ancient techniques continue to influence modern metal fabrication

- Courses offer hands-on experience in traditional and contemporary methods

- Understanding historical metalworking enhances technical skills

- Metal machining connects practitioners to a global artisan tradition

Discover the Rich History of Metalworking

Metalworking showcases human innovation spanning thousands of years. The craft of transforming metals has shaped human civilization2. From ancient cultures to modern techniques, metallurgy drives technological progress.

Metalworking’s origins date back to early human development. Around 6000 BCE, civilizations discovered sophisticated metal extraction and manipulation methods2.

The Bronze Age, from 3300 BCE to 1200 BCE, marked a critical period of technological advancement2.

The Origins of Metalworking Techniques

Early metalworkers created innovative techniques that changed manufacturing. Their methods included:

- Primitive smelting processes

- Rudimentary forging techniques

- Basic sheet metal forming

- Experimental casting methods

Key Historical Figures in Metalworking

“Innovation in metalworking has always been driven by human curiosity and creativity.”

Pioneering researchers made significant contributions to metalworking. Edmund Davy discovered acetylene, advancing metallurgical science3.

Sir Humphry Davy’s electric arc welding process was another groundbreaking development3.

Ancient Cultures and Their Metalworking Practices

Different civilizations developed unique metalworking approaches. The Industrial Revolution transformed metal production dramatically.

It introduced advanced techniques like the Bessemer process2.

| Civilization | Key Metalworking Technique | Significant Achievement |

|---|---|---|

| Ancient Mesopotamia | Bronze Casting | Advanced Weaponry |

| Roman Empire | Iron Forging | Architectural Innovations |

| Chinese Dynasties | Metallurgical Refinement | Sophisticated Tools |

Metalworking continues to evolve with new technologies. Computer-aided design and additive manufacturing are now crucial.

These advancements ensure metalworking’s vital role in aerospace and automotive industries2.

Courses to Enhance Your Metalworking Skills

Metalworking offers exciting opportunities for skill growth. Specialized courses can help you master Metal Stamping, Metal Finishing, and Welding techniques. These courses cater to beginners and experienced craftspeople alike.

Online vs. In-Person Metalworking Courses

Your learning journey can take multiple paths. Online courses provide flexibility for busy professionals. Virtual training sessions cost between $115 and $230.

In-person workshops offer hands-on experiences with direct instructor guidance. These workshops cover various skill levels and techniques.

- Virtual courses spanning 2-3 days

- Workshops covering various skill levels

- Specialized training in metalworking techniques

What You Can Expect from a Metalworking Course

Metalworking courses provide comprehensive training in essential skills. You’ll learn techniques like soldering, wire twisting, forging, and forming from experienced professionals4.

Professional development credits can reach up to twenty-four hours5. These courses equip you with valuable skills for your metalworking journey.

| Course Type | Duration | Skill Level |

|---|---|---|

| Basic Metalworking | 2-3 days | Beginner |

| Advanced Techniques | 5-9 days | Intermediate/Advanced |

Recommended Course Providers

Top metalworking education providers offer diverse training options. The Fabricators & Manufacturers Association provides certification exams and learning opportunities5.

Other respected institutions offer specialized workshops. These focus on Metal Stamping, Welding, and Metal Finishing techniques.

“Investing in skill development is the key to mastering metalworking craftsmanship.”

Tools and Materials Used in Ancient Metalworking

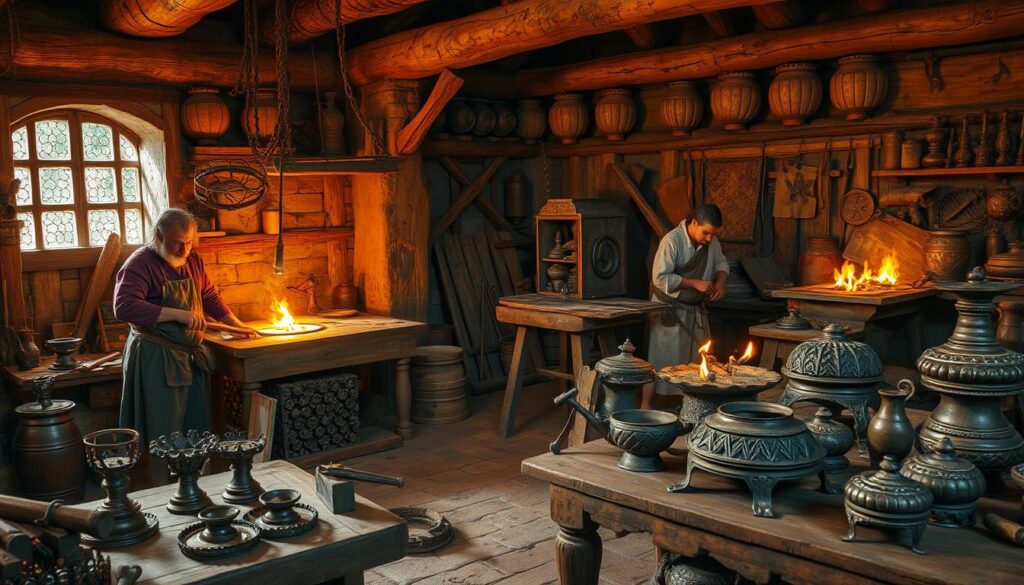

Metalworking showcases human innovation at its finest. Craftsmen developed intricate techniques for shaping metals using specialized tools. Their knowledge was passed down through generations6.

Early artisans’ skills shine through their use of ancient metalworking tools and materials. Natural copper and meteoric iron were among the first metals used. Each material offered unique qualities for creating tools6.

Essential Metalworking Tools for Beginners

Metal machining requires familiarity with fundamental tools:

- Hammers for shaping metal

- Anvils for supporting workpieces

- Bellows for controlling forge temperatures

- Tongs for handling hot materials

Common Metals and Their Historical Uses

Ancient metalworkers mastered forging and casting techniques. Early civilizations developed sophisticated metalworking practices. They transformed raw materials into functional and artistic objects6.

Metals offered unique properties for toolmaking:

- Copper: Readily available in nugget form

- Meteoric iron: Corrosion-resistant due to high nickel content

- Gold and silver: Primarily used for decorative purposes

Safety Precautions in Metalworking

Safety is crucial when exploring casting and metal machining. Wear protective gear and understand proper tool handling. Work in a well-ventilated space for a safe metalworking experience.

*”The art of metalworking is as much about respect for the craft as it is about technical skill.”*

How to Apply Your Metalworking Knowledge

Ready to turn your metalworking skills into creative projects? Metal fabrication offers endless possibilities for unique items. Your newfound expertise can shine through welding sculptures or forming functional tools78.

Dive into sheet metal forming for intricate designs and practical objects. The metalworking craft lets you explore various techniques7. Each project refines your skills and boosts confidence in your abilities8.

Connect with other metalworking fans to boost your learning. Join professional groups and local workshops to share knowledge. You’ll learn advanced techniques and get inspired by fellow craftspeople8.

Metalworking’s future blends traditional skills with new tech. Sustainable practices and innovative methods expand metal fabrication possibilities. Stay curious and keep learning for endless creative opportunities7.

FAQ

What are ancient metalworking courses?

What materials do I need to start learning metalworking?

Are metalworking courses suitable for all skill levels?

What can I create after learning metalworking?

What safety precautions are important in metalworking?

What’s the difference between online and in-person metalworking courses?

How long do typical metalworking courses last?

Are there opportunities to join metalworking communities after taking a course?

Source Links

- Metallurgy in pre-Columbian America – https://en.wikipedia.org/wiki/Metallurgy_in_pre-Columbian_America

- Metalworking Through the Ages: A Historical Journey – https://mjironworks.com/en/blog/metalworking-through-the-ages-a-historical-journey/

- No title found – https://www.thefabricator.com/thewelder/article/arcwelding/metalworking-throughout-history

- Class Listing | Metalwerx – https://metalwerx.com/class

- Hands-On Workshop: Metal Fabrication Fundamentals – https://www.fmamfg.org/training/certificates/hands-on-workshop-metal-fabrication-fundamentals

- Hand tool – Early Metals, Smelting | Britannica – https://www.britannica.com/technology/hand-tool/Early-metals-and-smelting

- What is Metalworking: Definition, History, Types & Applications – TechniWaterjet – https://www.techniwaterjet.com/metalworking-process/

- An Introduction to Metalworking Safety | SafetyCulture – https://safetyculture.com/topics/metalworking/